Click on the Pictures to see a larger view

Staff

Professor Vincent H. Arthaud is also involved in the meat research program at the University of Nebraska. The beef cattle carcass evaluation projects have been his responsibility for many years. Current studies have included the completion of a project related to grade standards for young bulls that have been fed on specified rations. At the present time, Professor Arthaud is collecting carcass data on steers, bulls, and short scrotum bulls, which is a part of his research area. Professor Arthaud's work has included lipid analysis on these same cattle carcasses. His office is also located in Marvel Baker Hall.

Dr. Charles H. Adams is in charge of undergraduate meat teaching and teaches Animal Science 117, 217, 311, and assists with students enrolled in Animal Science 419 or 819. Dr. Adams' office is in Marvel Baker Hall, the Animal Science building adjacent to the meat laboratory, since there is insufficient office space in the Loeffel Meat Laboratory. Dr. Adams joined the staff in 1947 and is a Professor of Animal Science. The assignments of Dr. Adams are generally in undergraduate teaching and advising although he also does research in the meat tenderness area.

Dr. Roger W. Mandigo is an Associate Professor of Animal Science and joined the staff in 1966. His responsibilities include teaching the graduate level courses in meats, teaching an undergraduate course in livestock and meat marketing, and advising the assignments made of special problems for senior and graduate students. Dr. Mandigo is also responsible for conducting meat research in the laboratory, which currently is involved with flaked, formed, and sectioned meat. Recently research has been completed on accelerated pork processing which involved the processing of pork to finished primal cuts prior to the chilling of those cuts. He is also in charge of the Nebraska Meat extension program. Professor Mandigo is responsible for all meat laboratory operations and complying with meat inspection regulations within the facility.

Mr. Jimmy W. Wise is working on his Ph.D. degree in the meats area at the University of Nebraska. In addition, he serves as instructor in the Animal Science Department and is currently responsible for the teaching of the meat grading and judging courses. He is also coach of the university meat judging teams and assists with the freshman course in live animal and carcass evaluation. He has additional assignments in the Nebraska meat extension programs.

The secretarial unit at the meat laboratory also functions as a retail meat sales operation. A substantial volume of meat from the teaching, research, and extension programs is sold through the meat sales unit.

The staff at the Loeffel Meat Laboratory in April 1972, is shown in this picture. In addition to Dr. Mandigo and Dr. Adams, secretaries, technicians, and graduate students are also shown in this picture.

Lower left:

Dr. Roger W. Mandigo, Larry C. Hinnergardt, a Ph.D. candidate, and Dr. Charles H. Adams. Standing in front of Dr. Adams is Loraine C. Mahoney, Technician and working toward her Masters degree. To Dr. Adams' left is Ella Mae Hartz, morning secretary; Mary Rupe, bookkeeper and meats sales person; and David C. Schleicher, Technician responsible for slaughtering and meat processing. Behind Mrs. Hartz is Jerry Popenhagen, a Master candidate. To his left is Michael C. Chesney, Technician responsible for the research areas of the laboratory. Behind Popenhagen is Keith R. Hansen, Ph.D. candidate. To Mr. Hansen's left is Richard O. Shuler, Ph.D. candidate and next to him is Dr. Ricardo Salazar, D.V.M., a Colombian student working on his Masters degree

Lower left:

Dr. Roger W. Mandigo, Larry C. Hinnergardt, a Ph.D. candidate, and Dr. Charles H. Adams. Standing in front of Dr. Adams is Loraine C. Mahoney, Technician and working toward her Masters degree. To Dr. Adams' left is Ella Mae Hartz, morning secretary; Mary Rupe, bookkeeper and meats sales person; and David C. Schleicher, Technician responsible for slaughtering and meat processing. Behind Mrs. Hartz is Jerry Popenhagen, a Master candidate. To his left is Michael C. Chesney, Technician responsible for the research areas of the laboratory. Behind Popenhagen is Keith R. Hansen, Ph.D. candidate. To Mr. Hansen's left is Richard O. Shuler, Ph.D. candidate and next to him is Dr. Ricardo Salazar, D.V.M., a Colombian student working on his Masters degree

Buildings

The meat laboratory can receive livestock either from trailers or low vehicles as well as standard size trucks. The livestock holding facilities are sufficiently large to allow the entire day's kill to be delivered in advance and held either indoors or outdoors. The loading dock facilities are available for receiving carcass meat or meat products from other packing plants and also for incoming shipments of equipment and supplies.

An additional facility has recently been added to the east side of the building. This facility includes a 15 ton compressor located in the smaller stainless steel unit to provide refrigeration for a chill chamber located in the larger unit. The chill chamber has access to the building and is self-contained with evaporators and three squirrel-cage fans. The chamber has an operating temperature capability of between minus 35° and minus 70° F. The normal operational temperatures are approximately 35 below zero with an air speed of about 10 miles per hour. The unit is equipped with its' own defrosting system. This chill chamber furnishes unique research capabilities for the meat laboratory.

The Loeffel Meat Laboratory was completed in 1953 and is dedicated to the memory of Professor William J. Loeffel, long-time meat researcher and former Department Chairman of the Animal Science Department, University of Nebraska. Loeffel Meat Laboratory is a modern, Federally Inspected establishment designed for both undergraduate and graduate teaching, research, and extension meat programs.

Classrooms

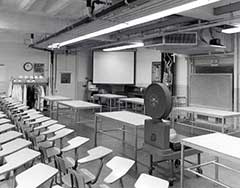

This is another view of the cutting room showing some of the 75 student tablet arm chairs that are located on risers. This room has a projection screen set up for the use of an overhead projector for visuals as well as for slides and movies. It is also equipped with dimmer lighting and is capable of being completely blacked-out with drapes. The temperature of this room is normally kept at 65°F in the summer time and 70°F in the winter time. This necessitates mid-day clean-up since we are not able to maintain the 50°F temperature required by USDA-MID.

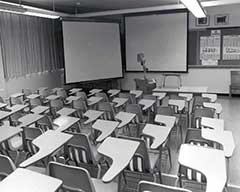

This is a view of the classroom on the top floor of the building. The room seats 65 students and is equipped with black-out curtains and has carpeted risers. Unfortunately, this room is not air conditioned.

A view from the rear of the classroom indicates two screens and an overhead projector. This room is set up so that two slide projector or two overhead projector viewings can be used at one time. A corner mounted screen is available so that the instructor can use the blackboard and the overhead projector at the same time.

Floors

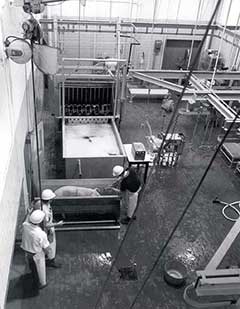

This is a view of the slaughter floor. In the wall at the immediate left can be seen the closed beef knocking chute gate. In the open doorway is the rollover hog stunning chute. The hog scalding tank can be seen with steam rising from it and the dehairing machine is at the far end of the tank. Beside the scalding tank is the electric stunner for the stunning of hogs. In the foreground can be seen the edible offal wash-up sink with overhead water spray valve. The personnel sink and knife and saw sterilizers are on the back side of the edible offal wash unit. The slaughter floor has a capability of slaughtering up to 8 or 10 cattle per day and up to 15 to 20 hogs per hour. Lambs are also slaughtered in small numbers. The slaughter room is completely well-placed so that drainage is adequate.

This is another view of the slaughter floor. The hysterectomy unit for taking SPF pigs immediately prior to normal birth can be seen in the distance on the right. The beef splitting saw hangs at the center of the picture. Floor stands used for hog evisceration and two of the storage cabinets are along the right wall.

This is an overhead view of the slaughter floor from the visitor's balcony, looking down on a hog about to be electrically stunned. After the hogs have been scalded and dehaired, they are dumped onto a gambreling table, not seen in the picture, directly behind the dehairing machine. The hogs are then hoisted to the rail and are moved to the eviscerating platforms where slaughter is completed prior to final inspection. The slaughter floor is not air conditioned but has a high capacity ceiling exhaust fan.

This is a view of the cutting room in Loeffel Meat Laboratory. Eight plastic topped cutting tables are in use in this laboratory along with two power saws, a two-stage grinder complex, packaging tables, and scales. This facility requires a mid-day clean-up to meet inspection regulations. This room is frequently used as a classroom so it is not desirable to maintain sufficiently low enough temperatures to process all day in this room without a mid-day clean-up.

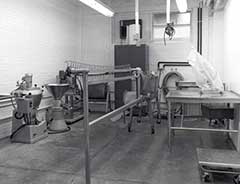

This is a view of the sausage processing room located on the lower floor of Loeffel Meat Laboratory. This room is a multi-purpose type laboratory which is air conditioned and can be held at temperatures near 50°F if necessary. On the left can be seen the corner of the sink. Next is the vacuum chop vertical cutting mill. This cutter is capable of handling gas injections for curing, vacuum chopping, or air chopping. The bowl is a tip-over bowl and can be dumped into tubs. Adjacent to the vertical cutting mill is a Hobart Emulsifier. This emulsifier with the conical shaped hopper is used in the production of fine emulsions. Beyond the emulsifier is a Comitrol Flaking machine, part of a new research project. A mixer can be seen in the immediate background next to the storage cabinet. In the center of the room is a Frank-A-Matic, which is used in the production of frankfurters and is on loan to the University of Nebraska. On the right-hand side is the distance is a grinder and stuffer. The stuffing table with a clipping machine is in front on the right.

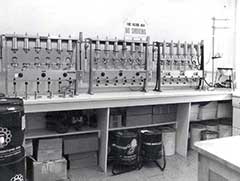

This is the lard rendering and cured meat operations room in the Loeffel Meat Laboratory. The Townsend skinning machines are seen on the far left along with cure ingredient storage barrels. At the far end of the room is a bacon slicer, a pumping table with pumping scales, and a Buffalo chopper. A black iron lard kettle can be seen on the far right between two stainless steel steam kettles. In the middle of the room are processing tables, a Ty-Linker, and a peeler. At the other end of this room, behind the photographer, are the spice and casing storage cabinets.

In the research laboratory area of the top floor is the fat extraction room. An eighteen plate Goldfisch fat extractor is shown in this view along with a large side-arm extractor. On the table along the opposite wall, out of view, is a Soxlet unit also used for fat extraction.

Adjacent to the fat extraction room is this room which has the autoclave, shown on the left, and the Kjehdahl unit. On the right is the Kjehdahl unit, which is used for nitrogen determinations for protein analysis as well as for TBA analysis for rancidity. In addition, this room also houses the titration equipment used for those determinations.

This is a view along one wall of the general research laboratory. Various pieces of equipment can be seen including a Warner-Bratzler shear, a small Hobart chopper for research samples, and a Spectronic 500 spectrophotometer with flow-through cell used for making colorimetric determinations. Beyond the desk and chair is a refrigerated centrifuge and, at the end of the room is the Barber-Colman 5000 gas chromatograph.

This is another view of the general research laboratory showing some of the equipment and the style and layout of the room. This large room is located on the top floor of Loeffel Meat Laboratory and also serves as the office for the laboratory technician.

Miscellaneous Pictures

This is a view of the holding pen area between the outside loading chutes and the slaughter floor. The floor scale is in the foreground and six holding pens are in the background. A knocking chute is at the extreme right. This area can be used in the winter time to hold animals for student evaluation when the weather does not permit students to work in the outside facilities.

This is a view of the coolers on the main floor of the building. In the immediate foreground on the right is the holding cooler area for chilling of hot carcasses. Sow carcasses can be seen hanging on the rail in this picture and are ever-present in the laboratory as a part of a cooperative program with the Department of Veterinary Science. The two adjacent doors on the right are to the walk-in freezers. In the back room, as seen through the open door, are beef carcasses hanging in the aging and storage cooler area. The marble top table on the immediate left is used to hold small meat cuts and edible by-products prior to their packaging for retailing.

Mr. Jimmy W. Wise is shown in the holding and storage cooler area evaluating some beef carcasses. The formica topped table seen in the foreground is one of two used during demonstrations for displaying cuts of meat for students. This cooler is normally held at about 35°F with a humidity in excess of 80%.

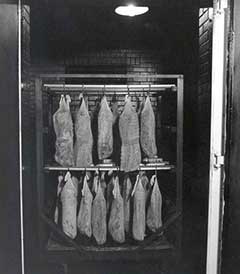

This is a view of the smokehouse on the lower floor of Loeffel Meat Laboratory. Smoked pork loins can be seen on the smokehouse truck. This smokehouse holds two trucks or two cages at a time, and it is a very good house for country curing of hams, bacon, and this type of product. Unfortunately humidity, temperature, and air flow controls were not provided for this house. Therefore, it is not as usable for processed and manufactured meats as is frequently needed in present meat processing procedures.

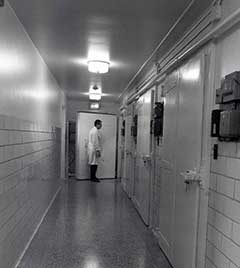

This is a view down the west hallway of the lower floor. The cured meat operations and lard rendering room is located on the left. There are four coolers shown on the right with Dr. Mandigo checking inventory. These coolers have a capability of various temperatures and are consequently used extensively in research work. Temperature range in these coolers is down to about 20°F. A light stability cabinet is housed in one of the coolers for doing work on exposure of cured meats to fluorescent lights. Others are used for various research studies.

This is a view of the cooking laboratory, which is adjacent to the general research laboratory. This laboratory is equipped with a large rotary-hearth oven under the hood at the back of the room. An electrical household range and a deep fat fryer are on the left against the far wall. In addition to these ovens, the laboratory is also equipped with a microwave oven, a quartz infrared oven, an electric charbroiler, and an electric griddle. Besides serving as a cooking facility for the research complex, this room also serves as a microbiology laboratory. An anaerobic incubator can be seen in the far corner on the right.